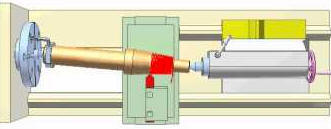

The tool is

ground and shaped at a particular angle which is needed in

taper turning. This method is used in mass production for

producing a small length of taper where accuracy is not

a criterion. The form tool should be set at right angle to

the axis of the work. The carriage should be locked while

taper turning by this method.

Advantage

-

Once the tool is made with cutting edge at particular angle, as long as tool is aligned perpendicular to the axis of the lathe, one can easily turn the jobs at required angle.

Disadvantage

-

There is only one angle value possible for the tool to be ground at a time.

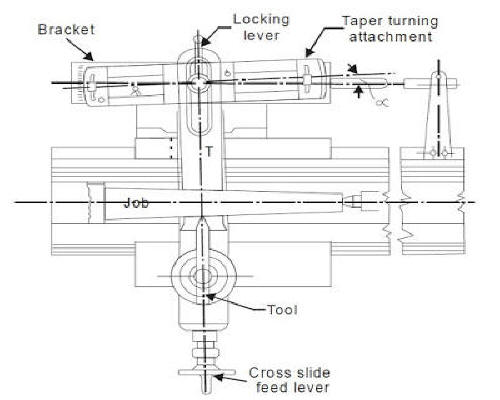

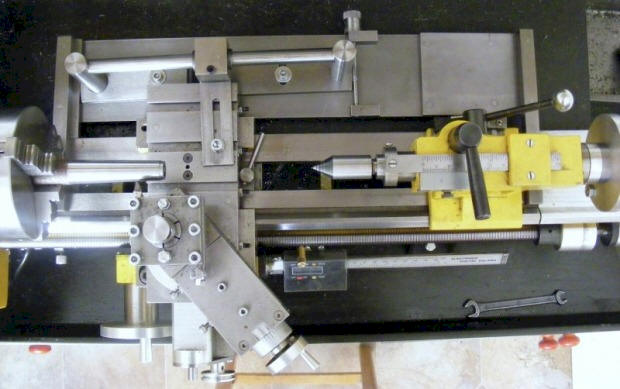

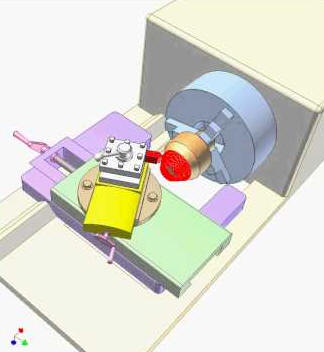

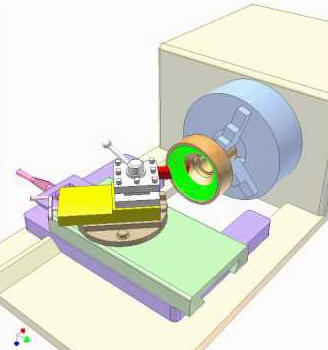

Generally short and steep taper are produced using this method. In this method the work piece is held in the chuck and it will be rotated about the lathe axis. The compound rest is swivelled to the required angle and then it will be clamped in position.

Advantage:

-

Both internal and external taper can be produced

-

Steep taper can be produced

-

Easy setting of the compound slide

Disadvantages:

-

Only hand feed can be given

-

Threads on taper portion cannot be produced

-

Taper length is limited to the movement of the top slide.

External taper

Internal taper