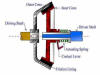

The clutch engaged by bringing two cone surface together in contact. A spring is provided on the driven shaft to hold the face of clutch in touch by producing required axial force. A forked lever is used to disengagement of the clutch.

- Cone Clutch used in various manual transmissions as synchronisers.

- They are used in various heavy machines as they can transmit high torque.

- These clutches are generally used in low peripheral speed applications.

- Cone clutches are commonly used in power racing boats.

- Cone clutches are used in racing and rallying vehicles.

- Cone clutches are used in some automobiles and other combustion engine transmissions.

- Small axial force is required to keep the clutch engaged.

- Simple design.

- For a given dimension, the torque transmitted by cone clutch is higher than that of a single plate clutch.

- One pair of friction surface only.

- The tendency to grab.

- The small cone angle causes some reluctance in disengagement.

|

|

|

|