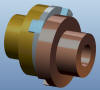

Advantages of

Oldham’s coupling

- Its size is

compact.

- Easy to

assemble.

- In case of

excessive load, the centre disc will be the one to break

first. Thus preventing the failure of other important

machine components.

- The centre

disc can be replaced easily and is inexpensive.

It can effectively absorb shocks and vibrations.

- It can

tolerate misalignment in shafts.

- Due to the

presence of plastic centre disc, the coupling becomes

electrically insulated.

- It is

economical.

|

| Disadvantages

of Oldham’s coupling |

- It cannot

tolerate angular misalignment.

- It cannot

tolerate high torque.

- Due to the

sliding movement, the centre disc is subjected to wear, thus

after a particular time period, it has to be replaced.

|

| Applications

of Oldham’s coupling |

- It is used

in a stepper motor.

- In robotics.

- Servo motor

applications.

- In printers

machines.

|

|