|

When

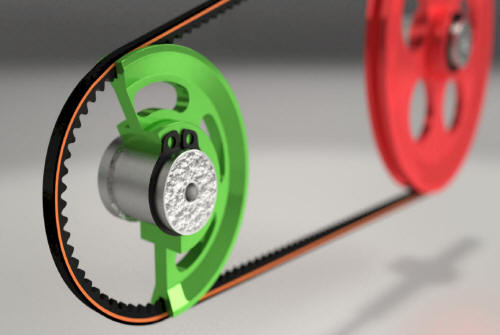

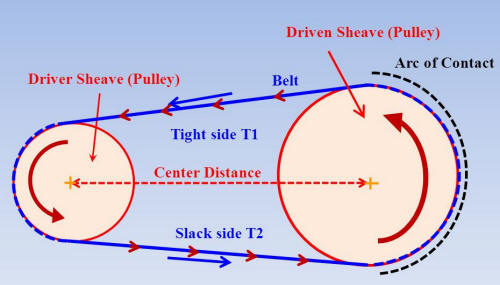

rotating around the pulleys, the belt is exposed to

different loads. The section of the belt in which the

belt is strongly pulled towards the driving pulley and

is thus exposed to a large tensile load is referred to

as the tight side. On the opposite section, the belt

moves away from the driving pulley and is slightly

relieved by its “pushing” effect. This belt section is

called slack side.

Tight side

-

The section of the belt in which the belt is strongly

pulled towards the driving pulley and is thus exposed to

a large tensile load is referred to as the tight side.

On the opposite section, the belt moves away from the

driving pulley and is slightly relieved by its “pushing”

effect.

Slack

side - The slack side is the side where tension on a

belt is low compared to the other side. In a flat belt

drive, driver pulley pulls the belt through the bottom

side and deliver it on the opposite side (upper side),

so the top side is always loose. One of the reasons for

doing so is to increase the angle of contact

Tension ration - The tension in the ratio between

the tight side T1 and the slack side T2.

Tension

ratio = T1/T2 (Newton)

Angle

of contact (wrap) - In the following, a single-stage

belt drive with two pulleys that are wrapped around by a

common belt is considered. The magnitude of this wrap is

described by the wrap angle

The

larger the wrap angle, the more adhesive surface the

belt has and the greater the frictional force or the

force that can be transmitted. However, it must be noted

that the pulleys of a belt drive are wrapped to

different degrees by the belt if the pulleys have

different diameters!

The maximum transmittable force is usually limited by

the smaller of the two pulleys (usually the driving

pulley), as this pulley has a smaller wrap angle

compared to the larger driven pulley. In addition, the

greater curvature causes greater bending stresses in the

belt, which also limit the transmittable belt force.

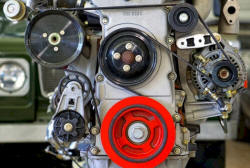

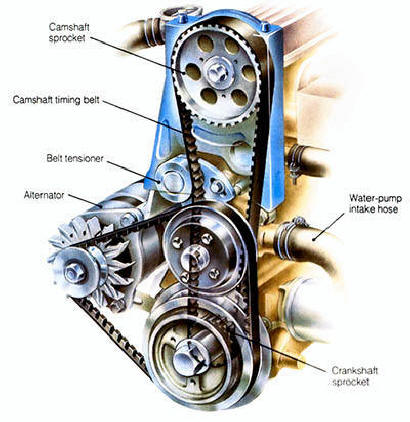

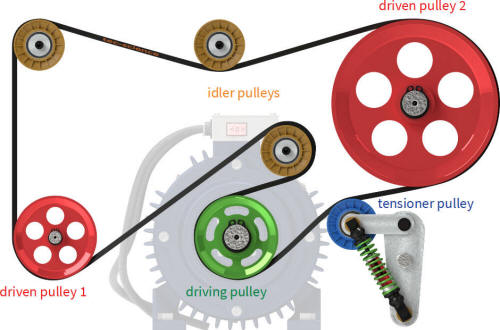

So called idler pulleys can be used to increase the wrap

angle. These are usually placed near the actual pulleys

to achieve the greatest possible wrapping effect. If

these pulleys are used to tension the belt at the same

time, they are also called tensioner pulleys.

Jockey

(idler) pulleys- If such pulleys are merely used to

deflect the belt, then these are generally referred to

as idler pulleys. Idler pulleys are used, for example,

in multiple drives in which one driving pulley drives

several other pulleys. Idler pulleys can also be used

for long belt lengths to reduce belt vibrations. Such

pulleys can also take over the function of a guide at

the same time, so that the belt does not jump off the

pulley. Such pulleys are called guiding pulleys or guide

rollers. Guiding pulleys often have protrusions (called

flanged pulleys) on the left and right, between which

the belt is held in track.

Tension

pulleys do not yet have a tensioning effect; certain

devices are required to achieve a tensioning effect

(also known as tensioning systems). Tensioning devices

are available in a wide variety of designs. The

tensioning systems shown in the figures above were each

designed with a simple spring mechanism. The springs

offer the advantage that the belt tension can adapt

dynamically to the operating state, e.g. strong load

changes. |