- Worksite health and safety practices when working with v-belt drives

- Good housekeeping working with belt drives

- Safety precautions to take when working with v-belt drives

- Appropriate personal protective equipment and explain its importance

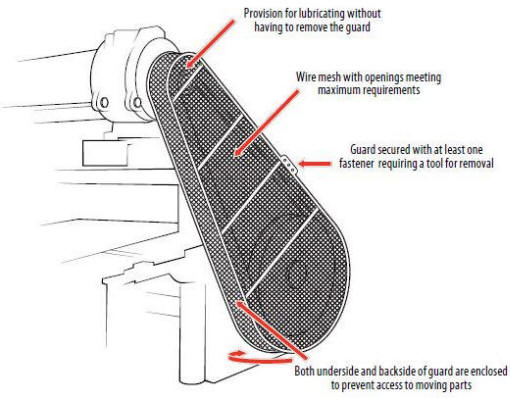

- Belt drive guards

- Clean work area when belt drive maintenance have been completed

Worksite health and safety practices when working with v-belt drives.

The aim of the OHS Act is to provide for the safety and health of persons at work and in connection with the use of plant and machinery. It further provides for the protection of people other than people at work from hazards arising out of or in connection with the activities from people at work.

Belt drive as in the case with any revolving machinery present considerable safety hazards. This is applicable not only in the maintenance of belt drives, but also during the normal operation of belt drives. The following are some of the safety hazards applicable to belt drives:

|

Normal operation of belt drives:

|

|

|

Maintenance and repairs of belt drives:

|

- Clean tools and place back in correct place after doing maintenance on belt drives

- Replace special equipment such as a Browning belt tensioner in its proper case for safe storing

- Clean work are after maintenance

- Dispose of broken belts as per company regulations - (rubber disposal regulations)

- Ensure proper colour coding of belt guards

|

|