|

|

Most plants will have maintenance planers. They will keep a record of all plant machines including belt drives. These records will include the following on a belt drive:

- When was the drive installed

- When was it last inspected

- Who did the inspection

- What parts where replaced

- All drawings and manufacturing manuals will be kept by planner

The maintenance planner will also prepare the following documents for the maintenance fitter:

- Job cards will be prepared by the maintenance planner

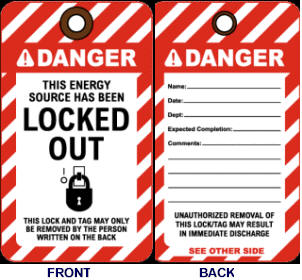

- Plant shutdown permission permit will be obtained

|

|

|

|

|

|

|

Straight Edge |

Various tools | Torque wrench | Browning tension device | Laser pulley aligner |