| Type of Gears -

Intersecting Shaft Gears - Helical Bevel Gear |

|

Video |

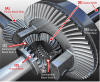

| A helical bevel gear is

a mechanical device that combines the features of a helical gear and a

bevel gear to transmit power between non-parallel shafts. This

combination results in a more efficient, quieter, and stronger gear

system than traditional straight-tooth bevel gears, making it suitable

for heavy-duty applications like industrial mills and mixers. |

| |

| Key features and

advantages: |

- Quieter

operation: The spiral teeth create smoother and quieter

engagement, reducing vibration and noise compared to straight-tooth

gears.

- Higher strength

and load capacity: The gradual tooth contact and higher contact

ratio allow for a more even load distribution, resulting in greater

strength and the ability to transmit more torque.

- Increased

efficiency: Higher tooth contact leads to less slipping and

greater efficiency.

- Suitable for high

speeds: Their robust design makes them ideal for high-speed

applications like automotive and aerospace systems.

|

| Disadvantages: |

- More complex and

expensive manufacturing: The curved teeth require specialized

machinery and more complex processes, making them more costly to

produce.

- Generates axial

thrust: The spiral design creates an axial thrust force that

must be absorbed by specialized bearings, adding complexity to the

gearbox design.

- Must be matched:

Spiral bevel gears are typically manufactured and sold as matched

sets. Using mismatched gears can lead to failure.

Sensitive to mounting errors: Proper and precise mounting is crucial

for performance and longevity, and errors can lead to increased wear

and failure.

- High tooth

pressure: While strong, they can be subject to high tooth

pressures, requiring careful design and maintenance.

|

| How they work |

|

Helical bevel gears work by

transmitting motion between intersecting shafts, typically at a

90-degree angle. Their curved, helical teeth mesh gradually, starting at

one end and spreading across the entire tooth surface, which results in

smoother, quieter operation and higher load capacity compared to

straight-toothed bevel gears. This gradual contact also reduces

vibration, making them ideal for high-speed and heavy-duty applications.

|

| Materials and

applications |

- Materials: They are

made from various materials, including plastic (like acetal or

nylon) and metals (like aluminum, brass, and stainless steel)

- Applications: They are

widely used in industries such as automotive, manufacturing, and

consumer electronics.

Plastic gears: These are lightweight, non-rusting, and can

operate without lubrication, making them suitable for food

production and medical equipment.

- Metal gears: These

offer greater strength, load-carrying capacity, and heat

resistance.

|

|

|