| |

|

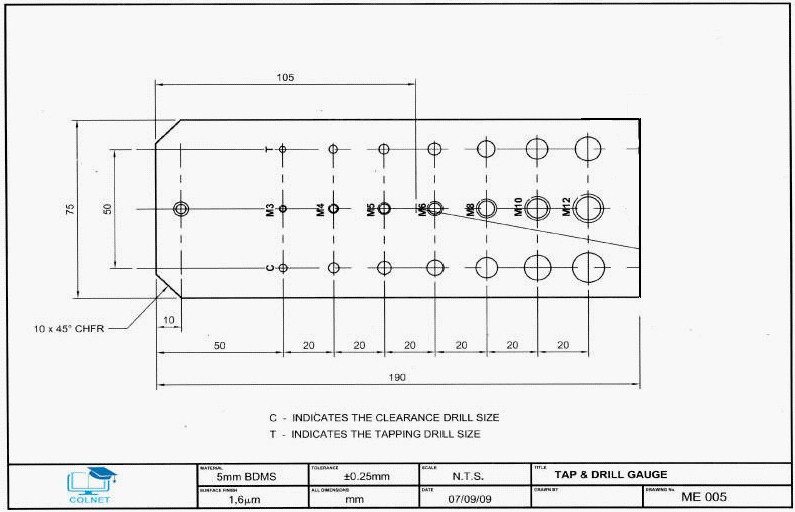

Interpret the drawing and

work instruction for the job: |

- Source stock material and

cut to approximate.

- Mark outline and file to

size and square

- Mark out all hole positions

- Clamp work in drilling

machine vice

- Drill holes to correct sizes

- Tap drilled holes

- Remove all sharp edges

(burrs)

- Clean work area and machine.

Return all tools and equipment back to its correct place.

|

|

Select and mark off the

material for the job |

- Select 5 mm flat sheet mild

steel material

- Mark off size of 192 x

77 mm

- Cut out using hack saw,

guillotine,

band saw or jig saw to cut to above size

-

File to adjacent sides square

-

Apply marking blue for clear view of marked of lines

-

Mark out to correct size 190 x 75 mm

-

Using file and engineering square file to above size

-

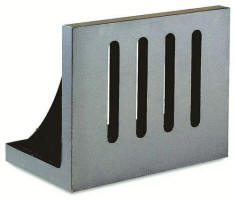

Mark out centre lines of holes to be drilled using surface

table, angle pate and vernier height gauge

-

Centre punch where holes must be drilled

|

|

Tools, equipment and

consumables needed:

Surface table |

Engineering square |

Steel Ruler |

Angle plate |

Vernier height gauge |

Scriber |

Hack saw |

Marking blue |

Ball peen hammer |

Band saw |

File |

Centre punch |

|