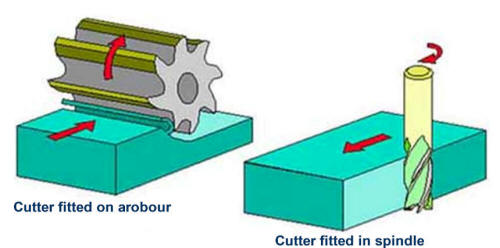

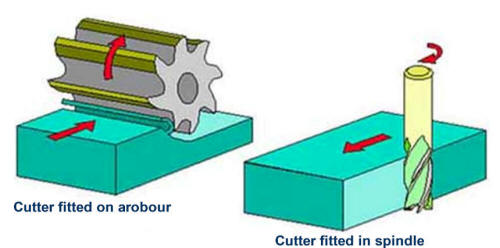

| Various

cutters can be used for surface milling. The larger the surface

are the larger the cutter. The following cutters can be used for surface

milling:

|

|

|

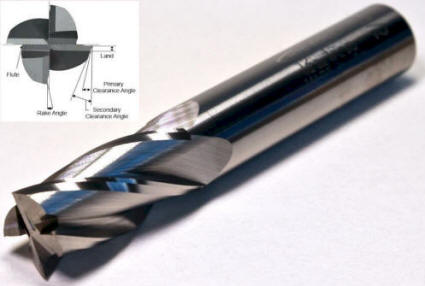

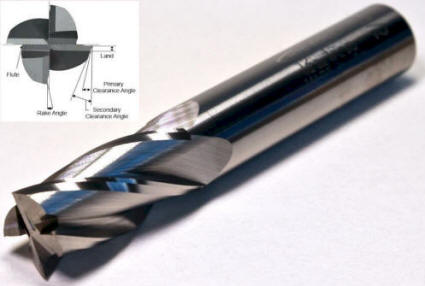

End mill |

|

| End mills

are those tools which have cutting teeth at one end, as well as on the

sides. The words end mill are generally used to refer to flat bottomed

cutters, but also include rounded cutters (referred to as ball nosed)

and radius cutters (referred to as bull nose, or torus). They are

usually made from high speed steel or cemented carbide, and have one or

more flutes. They are the most common tool used in a vertical mill.

It must be noted that the

cutting flute does not go all the way to the centre, and thus can not

plunge into the work. Cutter must be fed into the side of the

work.

|

|

|

Slot drill |

|

| Slot drills

are drill tips designed to be used with general machine applications.

Slot drills are also known as slot mills and are generally a two fluted

and flat-ended double-cutting tool with two radial cutting edges opposed

to each other. A

slot drill is just a 2-flute end mill used for cutting a slot, as per

the name, more clearance for the chips to come out of the back without

clogging then, there'll be one flute cuts over centre so it can be used

to plunge cut small distances too, to start slots in the middle of

material

|

|

| |

|

|

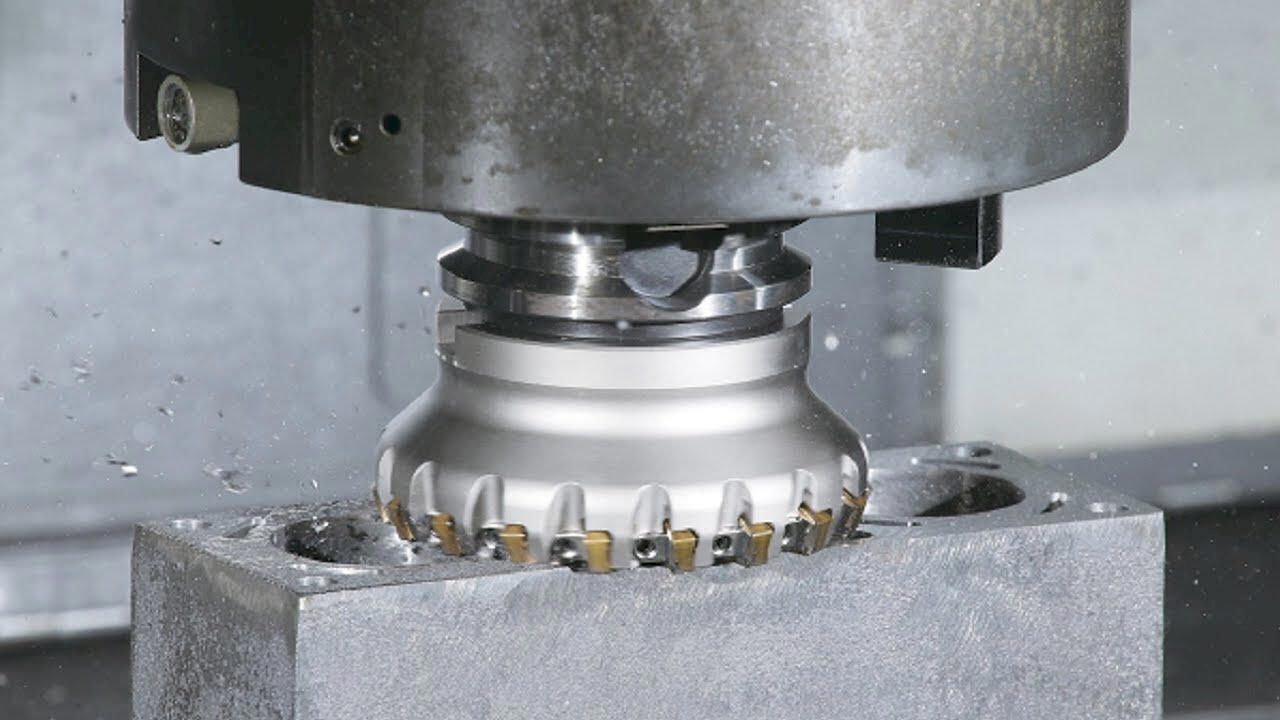

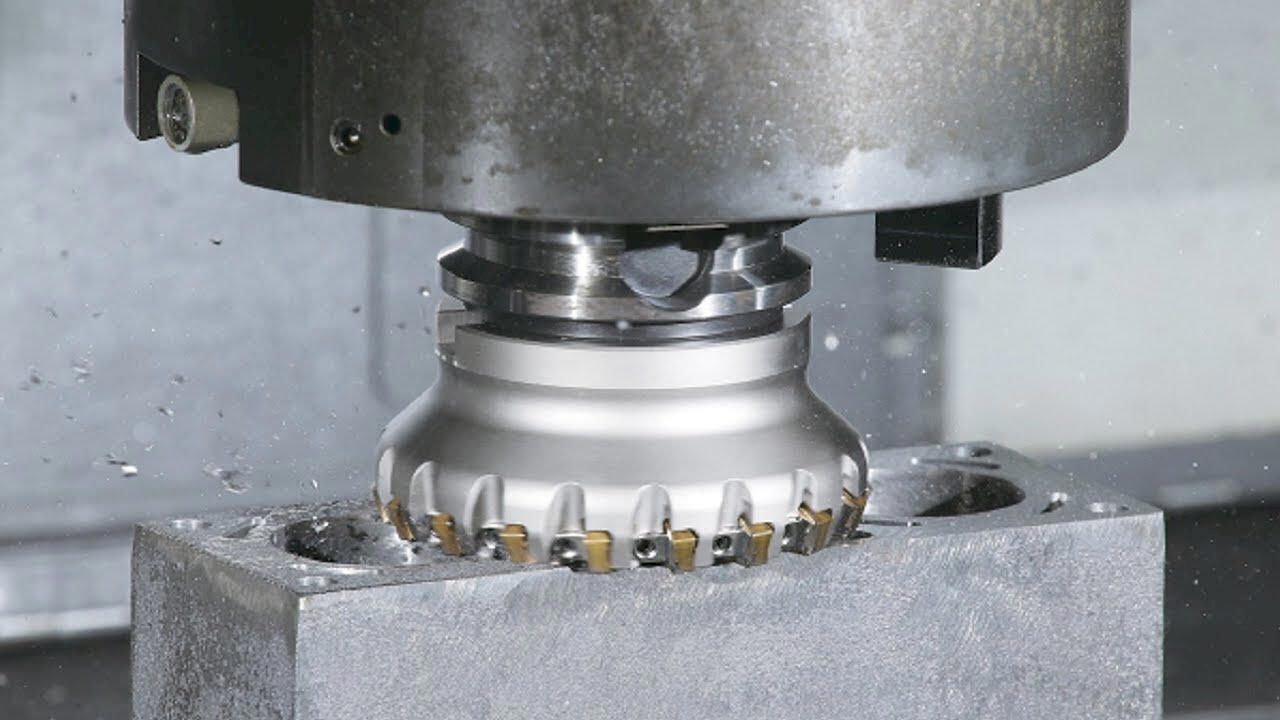

Rose cutter

Video |

|

| A rose

cutter is a large cutter with carbide inserts. They are suitable

for large surface milling and minimise time taken cutting surface.

|

|

| |

|

| Fly cutter

Video |

|

| A Fly Cutter

is any single point cutter that is used on a mill. The most common fly

cutters are used as surfacing tools.

Large surface area such

as engine cylinder head and block can be machined.

|

Milling a

engine head with fly cutter |