- Clear Away Chips

Before you mount a vice to your table, you will need to clear away all the chips. This can be done with either a brush or a vacuum.

Make sure to clean the T-slots too:

Finish up with either a quick wash down and/or wipe with a clean shop towel or paper towelling:

-

Clean the Table with a Stone

The next step is to stone the table top and bottom of the vice with a fine stone. A good, all-around stone is an oil filled, aluminium oxide stone. These are usually a combination stone that has a rough side and a fine side. Aluminium oxide stone with rough and semi-smooth sides for stoning a table. Since all you will want to do is check for nicks and high spots on the table, the fine side will work best for this step. Make sure to clean the table with a solvent or alcohol to remove any gunk or oil before you start to stone. -

Apply Rust preventative by coating the table top and bottom of the vice with a light coat of rust preventative. This can be sprayed on or wiped on with a shop towel. You are now ready to slide the vice on the table

-

Bolt the Vice to the Table

Position the vice on the table in line with the table T-slots and bolt slots on each side of the vice.

Slide the vice on to the table

Secure the vice to the table with two bolts and lightly snug both. You are now ready to square the vice to the table with an indicator.

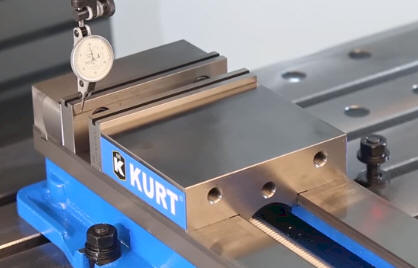

- Position your

indicator in the spindle or magnetic base. Remove the right side

bolt to create a pivot point.

Create a pivot point

Always indicate the hard jaw side of the vice close to the pivot point and with no more than one revolution, jog the table in the “Y” axis to bring the indicator to zero.

Set Indicator to Zero

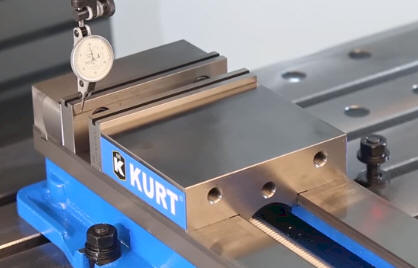

Next, jog the “X” axis to the other side of the vice. Tap the vice with a plastic or lead hammer so as not to damage the vice and bring the indicator to zero.

Tap vice to bring indicator to zero

Tap vice to bring indicator to zero on opposite end from pivot point

At this point, jog the “X” axis back to the pivot point side and jog the “Y” axis to reset to zero your indicator. Now jog the “X” axis back across the vice. If the vice is still off, tap the vice to bring the indicator to zero. Jog the “X” axis back to the pivot point side and if it is still off, jog the “Y” axis to re-zero the indicator. At this point you should be close to square with the table. Jog the indicator back to the opposite end and if necessary tap the vice to zero on the indicator. One last jog in the “X” axis back and forth across the jaw to double check and then slide the second bolt back in and snug it down.

Slide the other bolt in the slot and snug down

Jog the “X” axis across the face of the jaw and give it one more check, then tighten down both bolts.

The first couple times, you may need to do five or more sweeps across the face of the jaw to square the vice to the table. With practice, you will be able to do it in less than three with this method that will work 100% of the time.

These and other “Pro-Tips” are brought to you by the experienced staff at Southern Fabricating Machinery Sales, Inc.—where we are more than just sales.