| Pumps - Dynamic pumps - Centrifugal pumps |

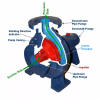

| A common centrifugal

pump setup is composed of one or more impellers connected to a rotary

pump shaft. This arrangement produces the energy needed to conduct fluid

in the pump operation and the associated piping. The impellers rotating in sync with the pump shaft transforms dynamic mechanical energy from the motor into the power of moving fluids. As most of the energy derived by the motor will be turned into kinetic energy of the pumped fluids, a share will be directed as potential energy in fluid pressure measured against gravity.

Centrifugal Pump Process |

| The major centrifugal pump distinctions are: Video |

|

| Axial and Radial Centrifugal Pumps |

|

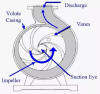

The major difference between

radial and axial centrifugal pumps are in their orientation. A radial

centrifugal pump allows an outward movement of the liquid channel in it.

The pumped flow is pressurized and leaves through downstream piping. By contrast, axial pumps provide fluid motion by a lifting force of their impeller vanes. |

| Single-Stage, Two-Stage, or Multi-Stage |

| The categorization of centrifugal pumps by stage is based on the number of impellers existing in their setup. |

| Single-Stage |

| This pump model houses only one impeller inside its casing, making maintenance relatively easy. A single-stage centrifugal pump is best adapted to low-pressure services where a significant flow rate is maintained. |

| Two-Stage |

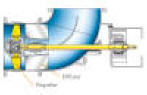

| A two-stage centrifugal pump has dual impellers working together to pump the process liquids. It is a suitable device for medium head applications. |

| Multi-Stage |

| Multistage pumps are defined as pumps in which the fluid flows through several impellers fitted in series. If the number of stages is altered at unchanged dimensions and speeds, the flow rate of such a multistage pump remains constant while the power input and head increase proportionally to the number of stages. |