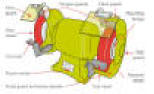

- Safety first - make

sure you unplug the pedestal grinder before you do anything else.

- Remove the safety

guards - this may take a little while if you have a lot of guards to

remove. You should have the tongue guard, eye guard and the wheel

guard to remove. Make sure to keep your screws organized and in a

safe place so they do not get lost.

- Next, remove the

tool rest.

- After

that, use a wrench to loosen the nut or bolt holding the wheel. You

may need to hold the other wheel when you do this to keep the wheels

from turning.

- Once you have that

done, take off the washer and pull the wheel off.

-

Inspect the shaft for corrosion and wear

-

Gently slide wheel onto the shaft, do not force it onto the shaft.

-

Tightened nut only by hand and not with wrench as it will tightened

by it self when starting the machine.

-

Replace guards

-

Perform a

truing operation to ensure the wheel is running centric with

out any vibration.

-

Readjust work rest to not more than 3 mm from the wheel.

-

Complete the machine maintenance register on work done.

|