|

SUBJECT

OUTCOME |

| 4.1

Use a centre lathe to produce a component |

| |

|

|

Explain the purpose of using

a centre lathe

-

With the aid of sketches the parts and components that

make up the lathe.

-

The different turning operations that can be performed on

a lathe and where relevant the advantages

and disadvantages.

|

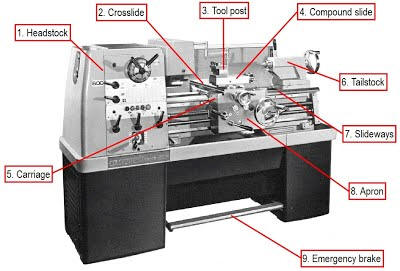

| The Centre Lathe. The Centre

Lathe is used to manufacture cylindrical shapes from a range

of materials including; steels and plastics. Many of the

components that go together to make an engine work have been

manufactured using lathes.

A lathe is a machine tool that

carries out many machine shop tasks. ... The lathe holds and

rotates the work piece about the centre line of these two

parts. It can also machine a part between its headstock and

tailstock centres. This is why we call it a centre lathe.

Video

Additional website 1

Additional website 2

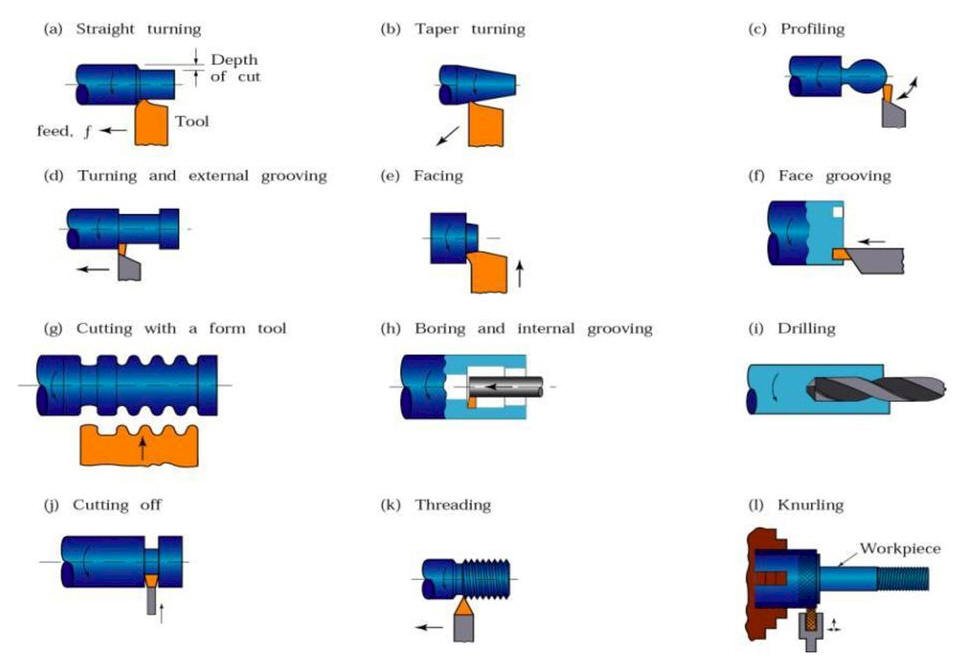

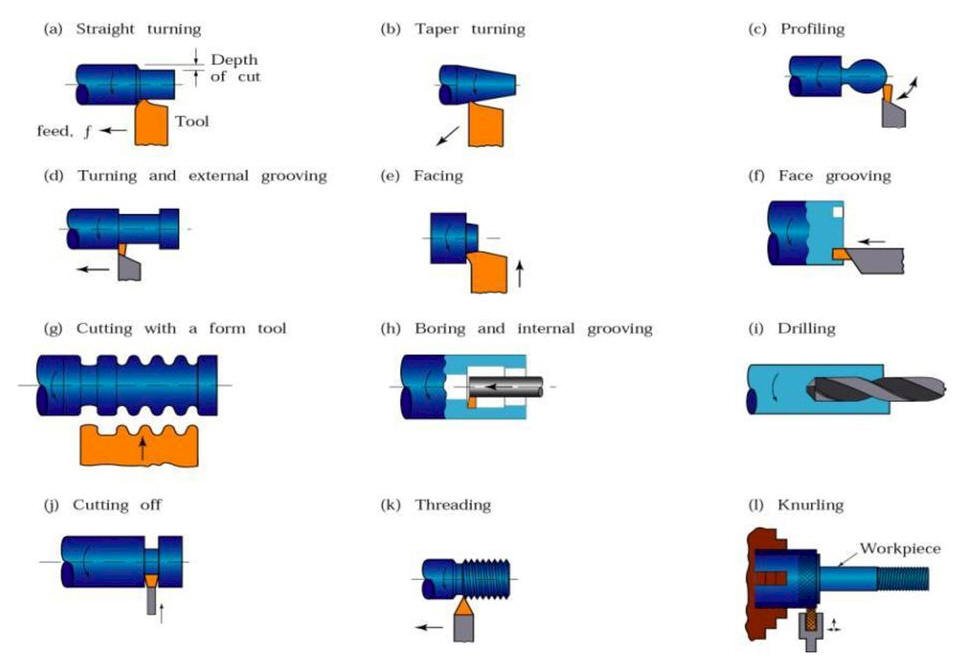

- Parallel turning

- Facing

- Drilling and reaming

- Boring

- Taper turning

- Internal and external

thread cutting

- Knurling

- Grooving

- Parting

- Profile (contouring)

cutting

- Chamfering

|

| |

|

Centre lathe parts |

| |

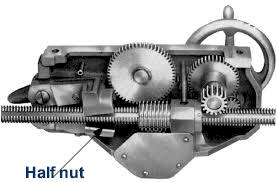

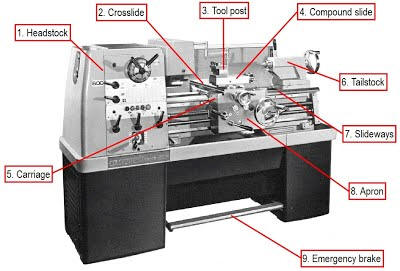

| There are many types of

lathe machine but each machine consist some basic part which

are essential for its proper working. These parts are bed,

tool post, Chuck, head stock, tell stock, legs, Gear chain,

lead screw, carriage, cross slide, split nut, apron, chip

pan, guide ways etc. |

| |

|

|

| |

|

Headstock |

| Head Stock The main function

of headstock is to transmit power to the different parts of a lathe. It

comprises of the headstock casting to accommodate all the parts within

it including gear train arrangement. The main spindle is adjusted in it,

which possesses live centre to which the work can be attached.

Different clamping components can be

attached to the spindle to hold work.

- It can adjust the spindle speed

- Adjustment for feed screw for thread

cutting

- Feed adjustment for automatic feed

- Emergency stop button

- Cutting fluid pump switch

|

|

|

Headstock spindle |

|

The spindle is the hart of

the centre lathe. It is rotating by means of the headstock motor

through the gearbox. It can rotate in both directions. It

can accommodate various clamping devices such as:

- Three jaw chuck

- Four jaw chuck

- Faceplate

- Dead centre for turning between

centres

- Collet

Thee jaw chuck

Four jaw chuck |

|

| |

|

|

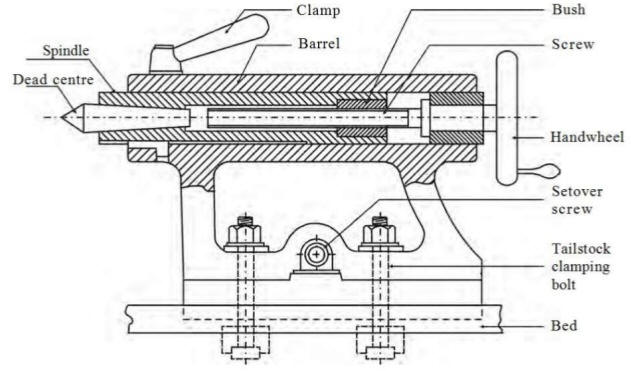

Tailstock |

|

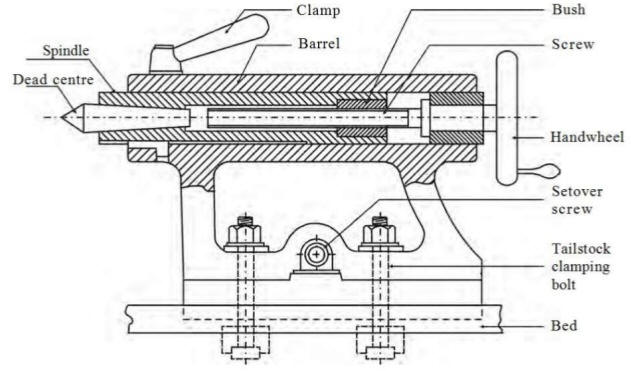

| It is usually used to apply

support to the longitudinal rotary axis of a work piece being machined.

A lathe centre is mounted in the tailstock, and inserted against the

sides of a hole in the centre of the work piece.

It can also accommodate the following:

- Drill bits for drilling

- Reamers for reaming

- Taps for cutting thread

|

|

| |

|

|

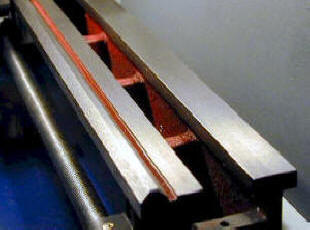

Lathe bed and gap bed |

|

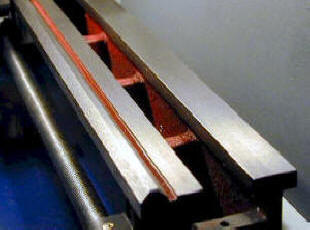

| The lathe bed is made from

cast iron and form a large part of the lathe. The lathe size are

express as the length of the bed. To be more precise the maximum

distance between the tailstock and headstock.

The bed supports he carriage as well as the

tailstock.

Gap bed is a piece of bed that can

be removed close to the headstock to accommodate work with large

diameter.

The bed can come in the following guides:

- Flat bed

- V-flat bed

- V-V bed

|

V-V bed |

V-flat bed |

|

| |

|

|

Carriage |

|

| The carriage houses the

saddle, the cross slide, and the apron. The main function of the

carriage is to position the tool along the lathe bed. This lever

controls the spindle's rotation and direction.

The following components make up the

carriage:

Saddle - Fit

on top of the bed and is accurately guided by the v-shaped guides in the

bed.

Cross slide is fitted to the

saddle and accommodates movement at right angels to the bed of the

lathe.

Compound

slide (or top slide) is usually where the tool post is mounted.

It provides a smaller amount of movement (less than the cross-slide)

along its axis via another feed screw. The compound rest axis can be

adjusted independently of the carriage or cross-slide. It can be set to

angels to accommodate internal and external tapers to be cut. It

also facilitate for the cutting of V-thread.

Tool post

is used to hold tools for turning and facing, boring, and knurling.

Quick change tool posts are specifically designed for the mini lathe and

may include a tool post and tool holders.

Apron is the

front face of the carriage. It is where the feed controls are located on

most manual lathes. The apron is also a housing for the gears and

associated mechanisms related to power feeding of the carriage and cross

slide |

|

| |

|

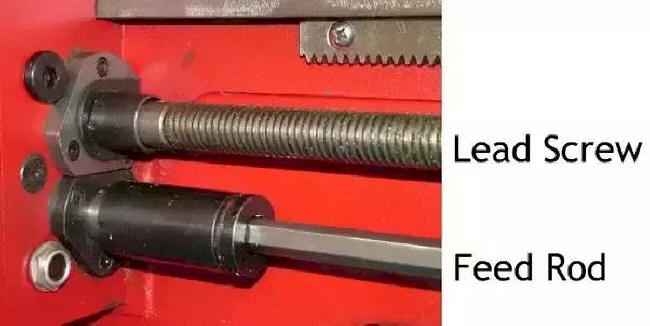

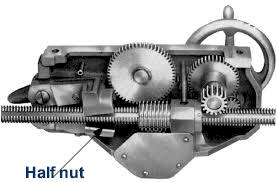

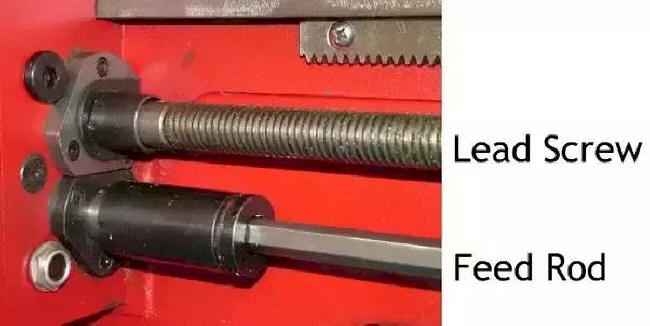

Feed shaft |

|

| The feed shaft (rod)

is a power transmission mechanism used for precise linear movement of

the carriage along the longitudinal axis of the lathe. This is

used to for automatic feed. The engagement levers is situated on

the apron

Lead screw The lead screw

of a lathe is used to advance the carriage of the lathe in time with the

rotation of the spindle. It is used to make threads by having different

gearing between the spindle and the drive for the lead screw. The half

nut on the apron is used to engage the lead screw.

|

|

| |

|

| Foot brake (emergency brake) |

|

| All lathes should be fitted

with emergency stop, foot or knee switches.

In case of an emergency even if hands are

tied up, all you need to do is to step on the foot brake.

The foot brake will cut the power and a

disk brake on the motor shaft will stop the rotation of the spindle.

NOTE: This brake is only for emergency

and not to be used for normal operation as this will put unnecessary

strain on the drive train of the lathe. |

|

| Graduated hand wheels |

|

| |

|

|

|

| Parallel turning

Video

Additional website |

|

Face turning

Video |

|

| Parallel turning is done

along the length of work. A single-point turning tool moves

axially, along the side of the work piece, removing material to form

different features, including steps, tapers, chamfers, and contours.

These features are typically machined at a small radial depth of cut and

multiple passes are made until the end diameter is reached.

|

|

A single-point turning tool moves radially, along the end of the work

piece, removing a thin layer of material to provide a smooth flat

surface. The depth of the face, typically very small, may be machined in

a single pass or may be reached by machining at a smaller axial depth of

cut and making multiple passes.

|

|

| |

|

|

|

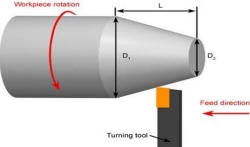

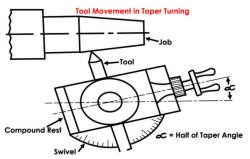

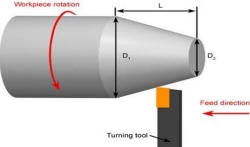

| Taper turning external

Video

Additional website |

|

Taper turning internal |

|

| A taper is a conical shape.

Tapers can be cut with lathes quite easily. There are some common

methods for turning tapers on an centre lathe,

Using a form tool: This type of tool is

specifically designed for one cut, at a certain taper angle. The tool is

plunged at one location, and never moved along the lathe slides. v

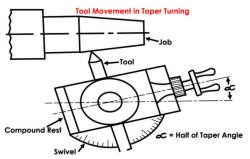

Compound Slide

Method: The compound slide is set to travel at half of the taper angle.

The tool is then fed across the work by hand, cutting the taper as it

goes. v Off-Set Tail Stock: In this method the normal rotating part of

the lathe still drives the work piece (mounted between centres), but the

centre at the tailstock is offset towards/away from the cutting tool.

Then, as the cutting tool passes over, the part is cut in a conical

shape. This method is limited to small tapers over long lengths. The

tailstock offset h is defined by

h = Lxsinα, where L is the length of work piece, and α is the half of

the taper angle.

|

|

Internal tapes can also be

machined on a centre lathe. You are limited to only using the compound

slide method or the taper turning attachment method.

Taper Turning Attachment is very much

popular and fits on all lathe machine. In ordinary straight turning, the

cutting tool moves along a line parallel to the axis of the work,

causing the finished job to be the same diameter throughout.

|

|

| Screw cutting

Video |

|

Parting off and Grooving

Video |

|

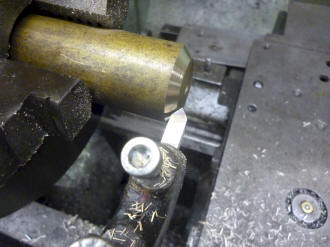

| A turning operation in which

a single-point tool, typically with a 60 degree pointed nose, moves

axially, along the side of the work piece, cutting threads into the outer

surface. The threads can be cut to a specified length and pitch and may

require multiple passes to be formed.

Square, ACME and buttress thread can also be

cut.

Internal as well as external thread can

be cut.

|

|

A turning operation, also

known as parting, in which a single-point cut-off tool moves radially,

into the side of the work piece, and continues until the centre or inner

diameter of the work piece is reached, thus parting or cutting off a

section of the work piece. A part catcher is often used to catch the

removed part. A turning operation

in which a single-point tool moves radially, into the side of the work

piece, cutting a groove equal in width to the cutting tool. If

the desired groove width is larger than the tool width, multiple

adjacent grooves will be cut. A profiling cut can be performed to smooth

the surface of multiple grooves. Special form tools can also be used to

create grooves of varying geometries. |

|

| |

|

|

|

| Profile turning

Video |

|

Drilling

Video |

|

| Profile turning is normally

done with a cutting tool that has been shaped according to the profile.

The cutting tool is difficult to make and is

time consuming.

|

|

The tailstock of a lathe can

be used for drilling, with the aid of a drill chuck or directly in the

tailstock spindle. If a long

piece of material has to be turned on a lathe then a centre drill is

used to produce the hole at one end. This allows the drilled end to be

supported by the tailstock centre. |

|

| Boring

Video |

|

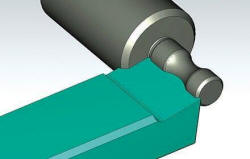

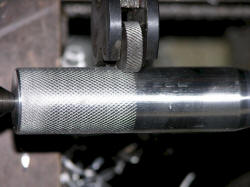

Knurling

Video |

|

| Boring is the process of

enlarging a hole that has already been drilled (or cast) by means of a

single-point cutting tool (or of a boring head containing several such

tools), such as in boring a gun barrel or an engine cylinder.

|

|

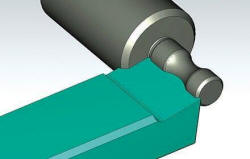

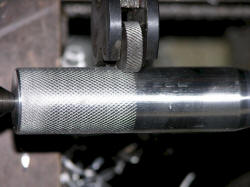

A knurling tool is used to

press a pattern onto a round section. The pattern is normally used as a

grip for a handle. Apprentice engineers often manufacture screwdrivers.

These have patterned handles, to provide a grip and this achieved

through the technique called knurling.

|

|