|

SUBJECT

OUTCOME |

|

4.4

Dismantle and assemble v-belt drives |

| |

|

|

|

Disassemble the

v-belt drive |

| |

- Ensure belt drive is

electrical end mechanical isolated -

See isolation

- Slack motor base bolts

and nuts so that motor pulley can move closer to machine

pulley

- The slack must be

sufficient for the belt to easily roll of by hand

- Note: Never use crowbar

or any other tools to remove belt as it is dangerous and

can also damage belt and pulleys

|

| |

|

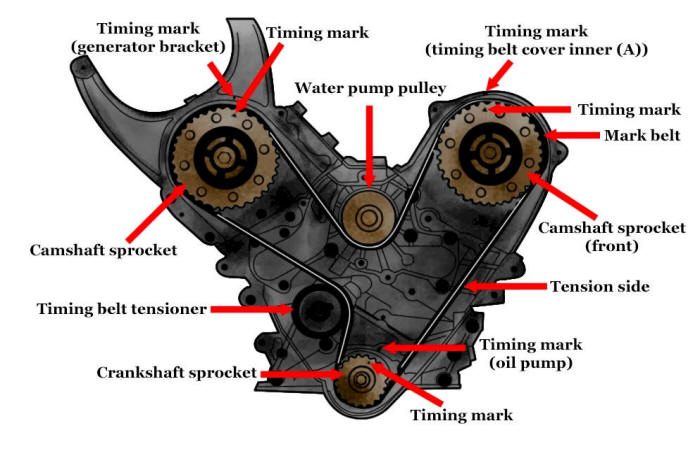

Identify v-belt drive assembly components |

| |

| Belt drives consists of

various components. It is important to recognise each

component, where it fit and what is its function. How

to fit and remove it safely and correct.

|

| |

|

Remove the belt drive

assembly |

| |

| Remove belt drive component

in a systematic sequins. Place all bolts, nuts, keys

and other components in a container for easy retrieval when

doing the assembly. If necessary mark components to

ensure correct position when doing reassembling. It is

also useful taking a cell phone photo of complicated belt

drive to assist in the reassembly of drive.

During disassembly check for

undue wear and misalignment.

|

|

Inspect parts for

non-conformances |

| |

Inspect belt -

Video

- Look for cracks,

fraying, or splits on the top cover. This is

normally due to belt age or excessive heat

- Look for signs of

glazing on the belt's sides. Glazed or slick belts can

slip, overheat or crack

- Twist a serpentine belt

to look for separating layers, cracks, or missing chunks

of the grooves on the underside

- Check for belt swelling

due to belt contamination by oil, grease and other

chemicals

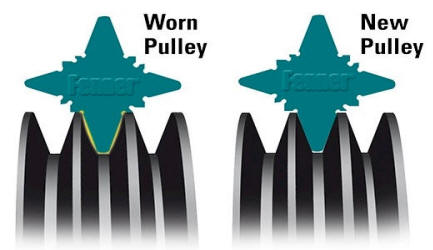

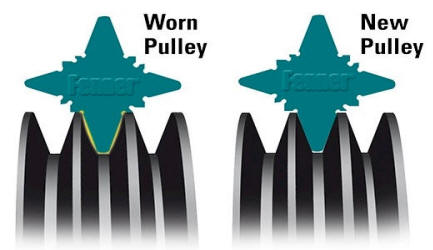

Inspect pulleys -

Video

- Check for worn

sidewall on pulley by using pulley gauge

- Check pulley for

corrosion

- Check keyway for

wear

- Check pulley for

cracks

- Check pulley for

wobble and balance that can lead to machine

vibration

- Check idler

(jockey) pulleys bearings for wear, noise and

lubrication leaks

Other belt drive

components inspections

- Motor base a

adjustment screws for wear and corrosion

- Drive guards for

wear and corrosion

- Drive and driven

shafts for wear and corrosion

- Inspect shaft

keyways for wear

- Inspect motor

and machine bearings for serviceability

|

|

Clean parts |

| |

| Clean drives with soap and

water, do not use any solvents to clean belt as it can

damage belt. If there is any belt contamination of oil

and grease, find the source of contamination and fix it.

Carbon tetrachloride can also be used for cleaning drive.

Note - Inhalation of its vapours can depress central nervous

system activity and cause degeneration of the liver and

kidneys |

| |

|

Assemble the belt

drive assembly and components |

| |

| Most belt dive failures is

the result of faulty installation of which the most common

faults are misalignment and wrong belt tension.

The following should never be

done when maintaining or installing belt drives:

- On a multi belt drive,

never install new belt with old belts as this will

result in uneven belt tension

- Do not mix different

type of belts on the same drive

- If possible, do not mix

different manufacturers belts, even if the sizes are the

same

- Never put belt dressing

on an EPDM-made serpentine belt. Belt dressing, and

other oils and solvents, may quieten the belt noise when

first applied, but these oils will actually cause the

belt's rib surface to become more aggressive once they

dry out, leading to even more belt noise issue

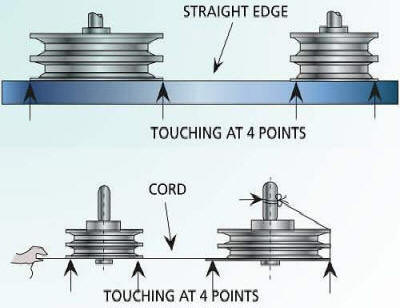

| Pulley alignment and belt

fitting

Additional websites

and

docs Pulley alignment is critical

for a effective belt drive.

Horizontal alignment:

- Move pulleys closer so

that belt can fit on pulleys by hand. Never use

any tool to force belt onto pulleys.

- Alignment must now be

done using the either a straightedge or laser -

video1

video2

- Loosen the motor

mountings bolts and adjust until all four points

indicated touch straight edge

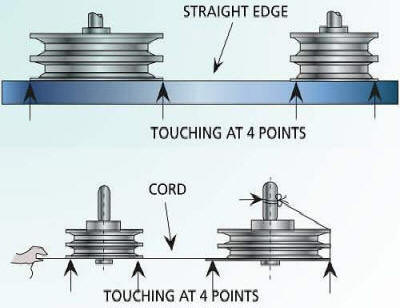

Figure (Top) shows

how a straight edge is used. Touching the driver and

driven sheaves at four points indicates good

alignment. Use a square positioned from the base up

to the sheave face to check if the sheave is

perpendicular to the base.

Figure (Bottom) indicates how a tight cord can be

used to check for pulley alignment. Tie the cord to

the driven pulley shaft and bring it around the

pulley face, bringing the cord to the driver pulley

face, a quick check can be performed to see if the

tight cord contacts the driver and driven pulley at

four points.

|

Horizontal alignment |

Motor horizontal

adjusters |

| |

|

|

|

Vertical alignment:

- Alignment must now be

done using the either a straightedge or laser

- Use shims under

motor base to achieve vertical alignment -

Additional website

- Some motors has

vertical jacking bolts to achieve alignment

Shim stock |

|

|

Belt drive tension

Correct belt tension is vital

important for an effective drive.

Tension

to low can lead to the following:

- Leads to

inefficient power transmission

- Belt wear

- Belt failure

- Possible

premature motor failure

- Wear on pulleys

- Heat build up in

belt drive and pulley

|

Tension to high

in belt drive can lead to the following:

- Excess

strain on the belts cause stretch that can

lead to premature belt failure

- Premature

belt wear

- Excessive

pulley wear

- Excess

bearings and shafts pressure causes

premature wear of these components

|

|

Adjusting

tension on belt drives -

Video

and

Additional website

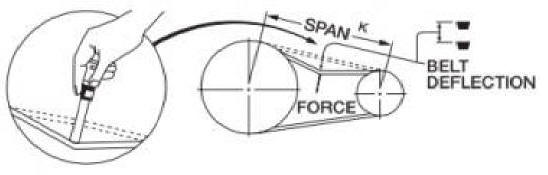

Force belt

deflection method 1

This

tensioning method relies on a Pencil

Gauge Tool (Browning tension gauge) and

the mathematical standards laid out in

this V-belt tensioning table.

-

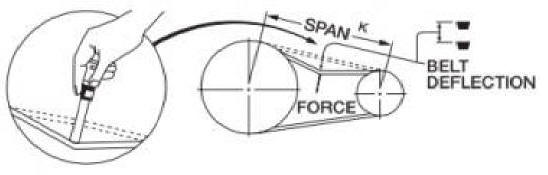

Measure the span length “K”

of your drive (See Figure 1)

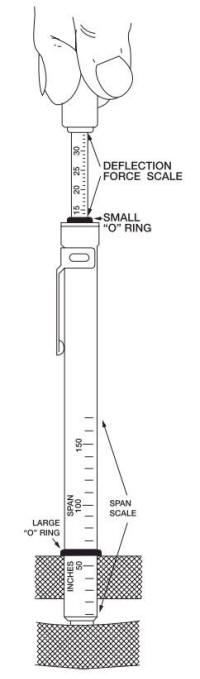

-

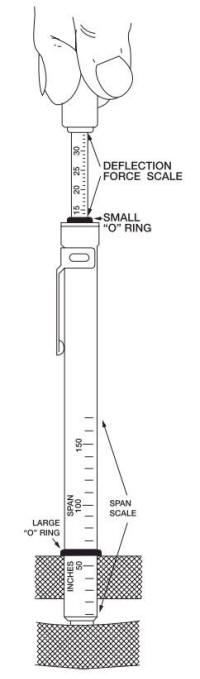

Slide the large O-ring to

the recommended deflection

distance on the scale and

slide the small O-ring up

against the barrel of the

gauge as shown in Figure 2.

-

Place the large end of the

tool onto the belt at the

centre of the span. Apply a

sufficient force to deflect

the belt until the large

O-ring is in-line with the

other belts. If this is a

single-belt drive, use a

straight-edge or taught

string for a “starting

point” reference

-

Then, release the pressure

and read the deflection

force from the position of

the small O-ring on the

plunger scale as shown in

Figure 2

-

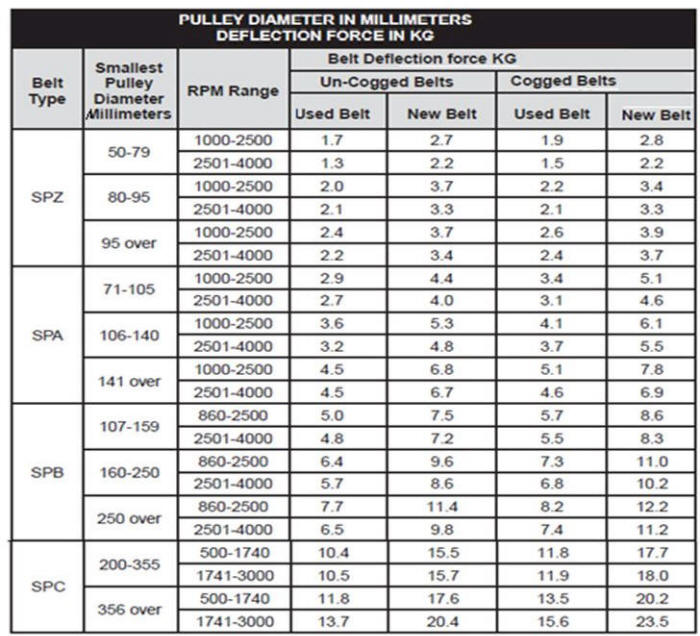

Compare this force with the

value given in the V-belt

tensioning table. If the

force is below the

recommended value, increase

the drive centre distance to

provide greater belt

tension. Reduce the centre

distance if there is too

much force

-

For example, for a 1000 mm

span, the deflection would

be 16 mm or

approximately,

PROS: Inexpensive ─ Precise

CONS: Time-Consuming ─ Tedious

Figure 1

Browning tension tool |

Figure 2 |

|

|

|

|

Force belt

deflection method 2

Using the thumb method

tensioning belt drive. The best

way to do this method? Don’t.

We mention the “thumb test”

method (using your hand or thumb

to apply pressure to the belt as

a way to judge whether or not it

has the correct amount of

tension) because many

traditional businesses still

practice this style of V-belt

tensioning.

When it comes to getting the

most life out of your belts and

maximizing the operational

efficiency of your business, we

do not recommend that anyone

rely on anything less than the

precision tensioning tools

mentioned above in methods 1

While the “pros” of this method

include the initial money and

time savings gained from this

simple procedure, as opposed to

investing in a tensioning tool,

the cost build-up of having to

replace your belts frequently

will ultimately overshadow this,

consequently increasing downtime

from belt failure.

PROS: Inexpensive Initial Cost ─

Fast ─ Easy

CONS: Unreliable ─ Inaccurate |

|

|

|

|

|

Car engine

alternator belt tension adjustment |

|

|

|

|

|

|