| |

| Bearings are classified as plain journal or

antifriction bearings. An antifriction bearing is a

bearing that contains moving elements to provide a

low friction support surface for rotating or sliding

surfaces. Antifriction bearings are commonly made

with hardened rolling elements (balls and rollers)

and races. |

| |

| Working principal of friction

bearing |

|

Video |

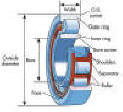

| Anti friction bearings consist of the following

basic elements.

|

| The races or rings |

In the case of ball bearings, the bearing has inner and

outer races and a set of balls. Each race is a ring with a

groove where the balls rest. The groove is usually shaped so

the ball is a slightly loose fit in the groove. Thus, in

principle, the ball contacts each race at a single point. |

| |

|

In the case of roller bearings, the bearing has inner and

outer races and a set of rollers. Each race is a ring with a

groove where the rollers rest. The groove is usually shaped

so the roller is a slightly loose fit in the groove. Thus,

in principle, the roller contacts each race at a line

contact point. |

| |

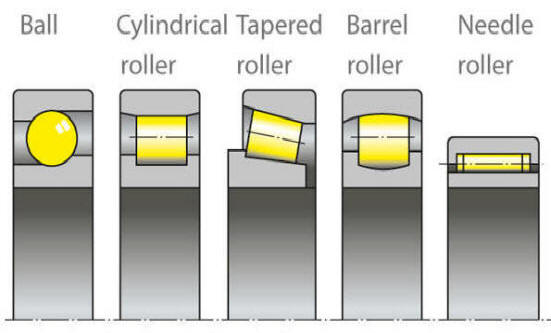

| The rolling element |

|

The rolling element is determined by the magnitude of the

load and direction of the load (axial or radial). |

| |

|

Ball

Balls are point contact. Most

commonly used rolling element. Relative large radial

loads with some axial loads. |

Roller

Rollers are line contact and thus

can carry very large radial loads with minimal axial

loads. |

|

Taper roller

Taper rollers are line contact and

will run in taper races. They can carry both

radial and axial loads. |

Needle roller

Needle rollers is similar to

rollers, their length is longer in relation to their

diameter. They can be used with races or

without. Normally used where radial space is

limited |

|

Spherical roller

(Barrel)

A spherical roller bearing is a

rolling-element bearing that permits rotation with

low friction, and permits angular misalignment.

Typically these bearings support a rotating shaft in

the bore of the inner ring that may be misaligned in

respect to the outer ring. |

|

|

|

|

|

Cage or retainer |

|

The ball bearing cage (also known as a ball bearing retainer

or ball separator – these are used interchangeably), is the

component in a ball bearing that separates the balls,

maintains the balls and rollers symmetrical radial spacing,

and in most cases, holds the bearings together. Solid

cages consist of brass, steel, light metal, sinter iron and

phenolic. Manufacture process for metal and phenolic cages

is consisting of turning and milling. Cages made out of

plastic materials are manufactured by injection moulding.

|

Press metal cage |

Machined cage |

Nylon cage |

|

|

|

|

Bearing

seals |

The primary functions of a bearing seal are to keep

lubricant in the bearing and bearing chamber contaminants

out. Bearings are pre-pact with grease in the factory

and will stay lubricated for the life of the bearing.

Some seals are integral to the bearing; others aren’t. The

focus here is on what to consider when selecting external

bearing seals. Key factors in making the right choice for an

application typically include:

- Bearing type (rolling or sleeve)

- Lubricant (oil or grease)

- Seal friction and consequent heating

- Shaft surface speed and finish

- Physical space available

|

|

Nylon seal |

Metal seal |

Rubber seal |

|

|

|

|

Type of anti friction bearings

|

|

|

|

|

|

|