| Milling machine parts |

|

||

| Additional website Video | |||

| The different milling machines has common parts. The main difference is in the pars is if it is a vertical or horizontal milling machine. | |||

|

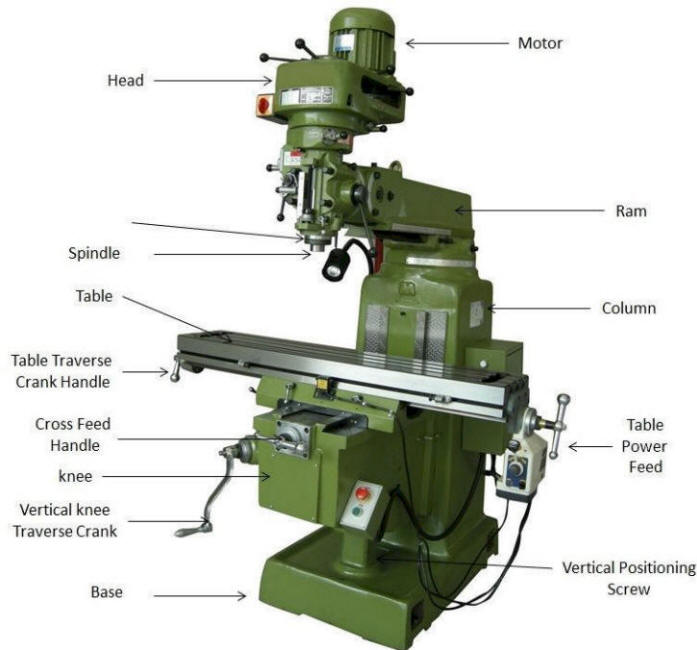

Vertical milling machine |

|||

|

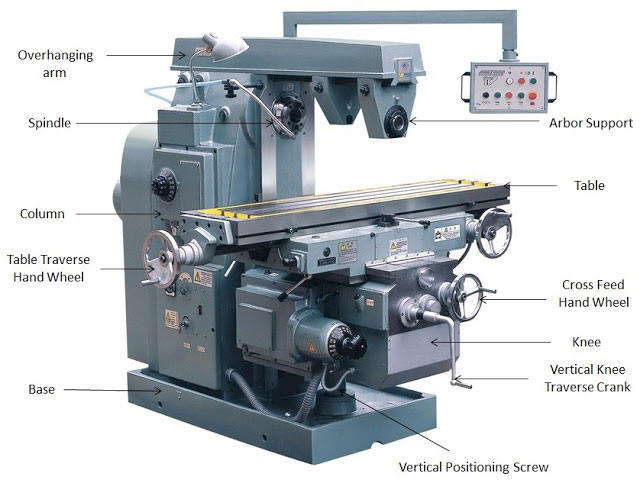

Horizontal milling machine |

|||

| The spindle motor is connected to the all geared head or belt drive of the milling machine. This motor will drive the spindle so that machining can be done. | |||

| Head | |||

| The head can be all geared for rapid spindle speed change, or belt driven with various pulleys sizes for different spindle speeds. The all geared head is easy to use as changing gears is easy compared to moving belts to obtain different spindle speeds. | |||

| Ram or overarm | |||

It is a horizontal beam present at the top face of the

column. It may be a single casting which slides on the

dovetail ways present on the top face of the column.

|

|||

| Column and base | |||

Column including base is the main casting that supports all

other parts of milling machine.

|

|||

| Knee | |||

It is a casting that supports the saddle and table. All

gearing mechanism is enclosed within the knee.

|

|||

| Saddle | |||

The saddle is present on the knee and supports the table. It

slides on a horizontal dovetail on the knee and dovetail is

parallel to the axis of the spindle ( in horizontal milling

m/c).

|

|||

| Power Feed Mechanism | |||

It is the knee which contains the power feed mechanism. It

is used to control the longitudinal ( left and right),

transverse ( in and out) and vertical (up and down) feeds.

|

|||

| Table | |||

It is a rectangular casting which is present on the top of

the saddle.

|

|||

| Spindle | |||

It is the shaft that is used to hold and drives the cutting

tools of the milling machine.

|

|||

| Arbor support | |||

It is a casting with bearing that supports the outer end of

the arbor. It also helps in aligning the outer end of the

arbor with the spindle.

|

|||

| Vertical positioning screw | |||

| The vertical positioning screw is used to position the table on the y axis. The table is moved up and down using the vertical knee transverse crank. | |||

| Cross feed | |||

| The cross feed is used to position the table on the z axis. The table is positioned on the z axis using the cross feed handle. | |||

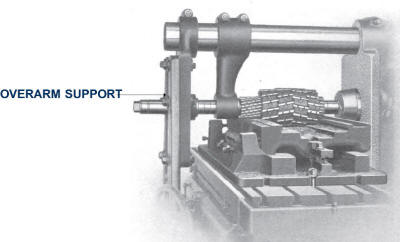

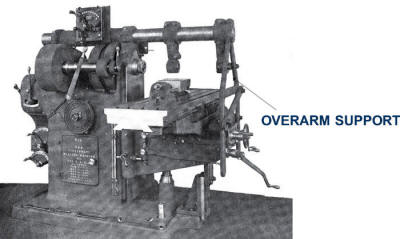

| Overarm support | |||

| The overarm support assist when the overarm is adjusted far over. It bolts on to the overarm an then onto the bed. Is is deployed to reduce vibration especially during gang milling | |||

|

|

|||

TVET COLLEGE SUPPORT

MILLING MACHINE