|

Milling Machine

Quality checks Exceptional quality comes from perfecting the smallest details. Every stage in the production chain from raw materials inspection to machining, testing, final product assembly and delivery must repeatedly pass specialized tests and strict quality control procedures to ensure every milling machine is defect free. These rigorous quality controls extend machine life and improve the overall functionality and value of machines. |

||||||||||||||||

| Correct measuring tools | ||||||||||||||||

| Correct measuring tools must be selected for measuring different dimensions and machining operations. The selection of measuring tools will depend on the tolerances given on drawings. The following are some of the operations and measuring tools that can be selected: | ||||||||||||||||

|

||||||||||||||||

| Go no go gauges can also be used during final inspection without measuring work. This can be performed by semiskilled staff. | ||||||||||||||||

| Surface finish Videos | ||||||||||||||||

|

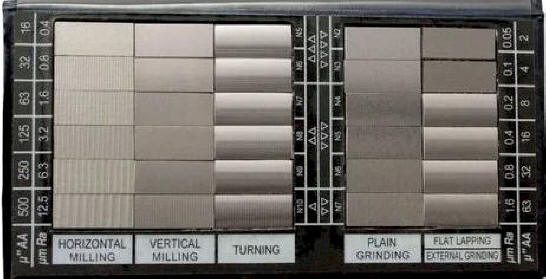

Surface finish, also known as surface texture or surface

topography, is the nature of a surface as defined by the

three characteristics of lay, surface roughness, and

waviness. Each manufacturing process (such as the many kinds

of machining) produces a surface texture. A surface comparison block can be used. This method is very subjective and is increasingly been replaced with surface texture gauges. |

||||||||||||||||

|

||||||||||||||||

TVET COLLEGE SUPPORT

MILLING MACHINE