| Cutting fluids | |||||||||||||||||||||||||||||||||||||||||||||

| Videos | |||||||||||||||||||||||||||||||||||||||||||||

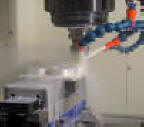

| Cutting fluids are used to reduce friction, through lubrication, which is a common problem during machining processes, and occurs at the contact between workpiece and the cutting tool. | |||||||||||||||||||||||||||||||||||||||||||||

| Advantages of using cutting fluid: | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| Properties of a good cutting fluid: | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| Ideal cutting fluid for specific martial: | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| Types of cutting fluid: | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| These oils are non-emulsifiable and very useful in machining operations where they function in undiluted form. Their composition is a base mineral or even petroleum oil. Often they contain polar lubricants like vegetable oils, fats and esters.They may also contain extreme pressure additives including sulphur, chlorine, and phosphorus. To achieve the best lubrication use straight oils however they may have poor cooling characteristics. | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| They do not contain mineral oil base or petroleum. Instead, they’re formulated from the alkaline organic and inorganic compounds alongside additives to prevent corrosion. They function well in their diluted form. Of all the varieties of cutting fluids, synthetic fluids offer the best cooling performance. | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| Soluble Oils usually form an emulsion after mixing them with water. The resulting concentrate contains emulsions and a base mineral oil to produce a stable emulsion. They function well in their diluted form and offer a great lubrication in addition to heat transfer performance. They are the least expensive and are the most widely used fluids in the industry. | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| These fluids are basically a combination of the soluble oils and synthetic fluids. Besides, the heat transfer performance and cost of the semi-synthetic fluids falls between those of the soluble and synthetic fluids. | |||||||||||||||||||||||||||||||||||||||||||||

TVET COLLEGE SUPPORT

DRILLING MACHINES