|

Drilling operations |

|

Drilling is an operation of making a circular

hole by removing a volume of metal from the job by cutting

tool called drill. A drill is a rotary end-cutting tool with

one or more cutting lips and usually one or more flutes for

the passage of chips and the admission of cutting fluid. |

|

Videos |

|

|

Types of Drilling Machine Operations: |

|

|

|

|

|

Centre drilling |

Centre drills

are usually double sided drills with a 60' stepped point,

held in a drill chuck or collet chuck in a lathe or

drilling machine.

The purpose of the centre drill is to create an accurate

centre hole in the face of a job so as a live centre can be

inserted to support the weight and load of the job, whilst

turning it.

Longer jobs generally require a live centre from the

tailstock of the lathe to support the job, which prevents

chatter and run out.

Centre drills can also be very useful in spotting or

starting a precise hole, which will also give a chamfer on

the hole.

Centre drills come in British Standard Sizing ( No.1 -

No.6); eg. No.3 centre drill; are also available in metric

sizes. |

|

|

Drilling |

| Drilling is an

operation of making a circular hole by removing a volume of

metal from the job by cutting tool called drill. A drill is

a rotary end-cutting tool with one or more cutting lips and

usually one or more flutes for the passage of chips and the

admission of cutting fluid. |

|

(See drill bit terminology) |

| |

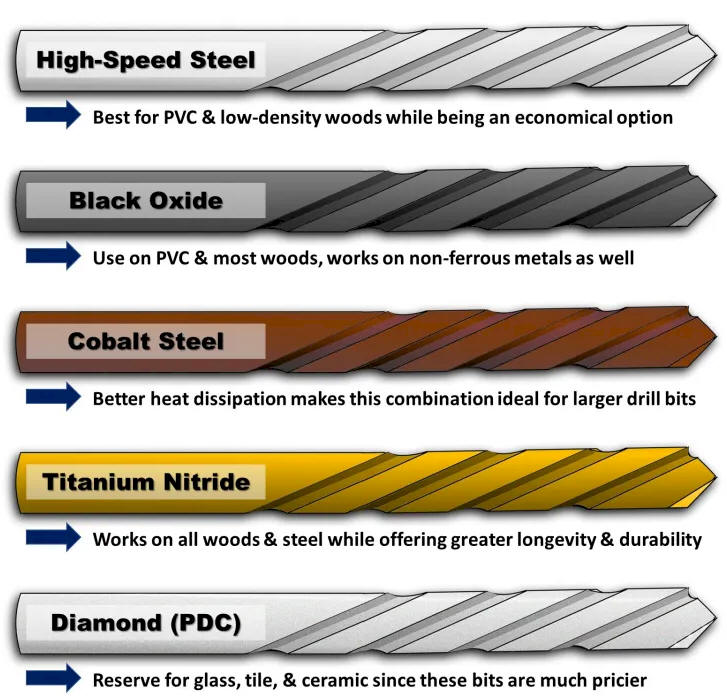

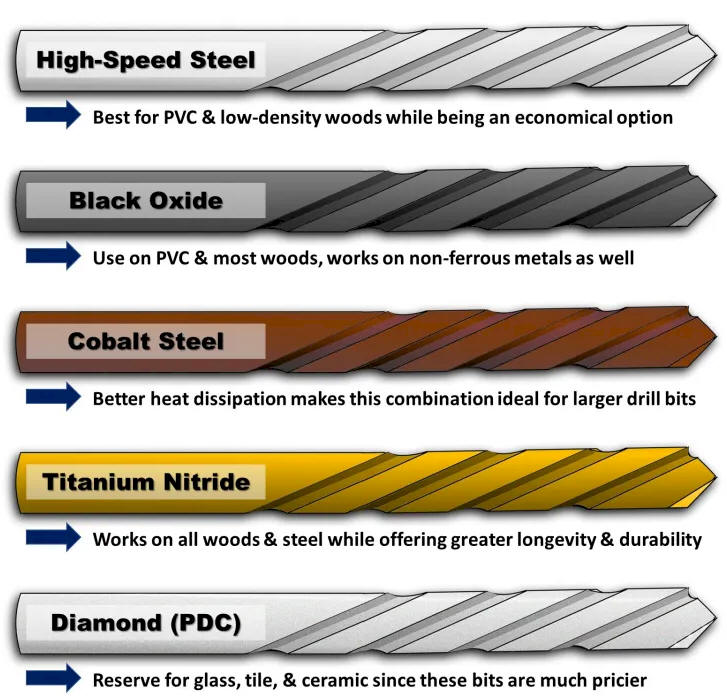

| Drill bit

material |

| Drill bit

material is depended on the type of material that is been

drilled: |

|

|

| Masonry

drill bit (cement, tiles) |

When you buy a

drill bit for concrete, getting the right one to achieve the

best results possible is important. A formidable drill made

of a hard metal such as tungsten carbide is necessary

to drill through stone, granite, marble, or granite. Masonry

drill bits are also specifically designed for stone and can

effortlessly bore through these challenging materials.

These drill bits recommended all feature carbine tungsten as

the primary material. These bits can endure hard stone

drilling. Wide flutes on masonry drill bits enable them to

pull large amounts of material away from the bit as they

drill, preventing particles from jamming it. |

|

|

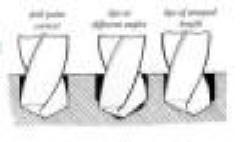

| Drill angels |

|

The two most common drill bit point angles

are 118 degrees and 135 degrees. The difference between the

two is the shape; a 118-degree bit is steeper, more pointed

and has a smaller chisel.

The 118-degree bit cuts more aggressively and

is generally used for drilling into soft material like wood.

Although it can puncture through steel, if used for this,

the steeper cutting angle also will cause it to dull more

quickly.

A 135-degree bit typically is used for

drilling into harder materials, because the pitch makes it

easier to drill repeated holes into tougher material.

Drilling into thin plate material also

require a drill bit with a large included angle

It is important that cutting lips must be of

equal length to ensure holes are correct size, If

cutting lips are not equal it will lead to over sized, and a

lot of chatter during drilling. |

|

|

|

|

|

|

Reaming

(see

reaming detail) |

|

This is finishing of a drilled hole in order

to obtain the specific size, fine surface, and making the

diameter the same size form end to end. The sufficiently

smooth hole is desired and called will be called a precision

hole as greater accuracy is required. |

|

|

|

|

|

Tapping

(see

tapping detail) |

This drilling machine operation is by

creating tapped (threaded) hole on a workpiece. It is

achieved by producing a non-tapped hole on the material,

using a specified size drill bit. A tapping attachment will

then be used to create the threading using a standard

drilling machine.

This tapping attachment is held in the spindle of the drill

press, which is accurately centres on the drilled hole. |

|

|

|

|

|

|

|

Boring |

|

Boring operation is performed to enlarge the

diameter of the existing hole which means it is always

performed after drilling. |

|

|

|

|

|

|

|

Counter boring |

Counter boring is the process of using

counter bores on a drilling machine to create a hole over

the screw clearance. This newly formed hole is designed to

let the screw rest in its place and not stick out.

Creating counter bores is achieved by using the drilling

machine, which uses drill bits that have a tip. Creating

counter bores is relatively simple. However, you must know

when to stop. Otherwise, you may make a hole that’s too wide

and can’t grip the fastener properly.

A counter bore allows you to completely hide the cap screw

underneath the surface. This way, the head of the cap screw

does not interfere with the design of the product and can

help the finished product look more aesthetically pleasing. |

|

|

|

|

|

|

|

Counter sinking |

|

Countersinking a hole is to cut a conical

hole into a metal object. This process is normally used to

create space for the head of a screw or bolt to sit flush

with the surface of the material or to clean away burrs left

from drilling and tapping. |

|

|

|

|

|

|

|

Spot facing |

|

Spot facing is a machined feature in which a

certain region of the workpiece (a spot) is faced, providing

a smooth, flat, accurately located surface. This is

especially relevant on work pieces cast or forged, where the

spot face's smooth, flat, accurately located surface stands

in distinction to the surrounding surface whose roughness,

flatness, and location are subject to wider tolerances and

thus not assured with a machining level of precision.

The most common application of spot facing

is facing the area around a bolt hole where the bolt's head

will sit, which is often done by cutting a shallow counter

bore, just deep enough "to clean up" that is, only enough

material is removed to get down past any irregularity and

thus make the surface flat.

Other common applications of spot facing

involve facing a pad onto a boss, creating planar surfaces

in known locations that can orient a casting or forging into

position in the assembly; allow part marking such as

stamping or nameplate riveting; or offer machine-finish

visual appeal in spots, without the need for finishing all

over |

|

|

|

|

|

|